1、 Introduction to butt welding and socket welding connection methods for valves:

The welding connection methods of valves are divided into two types: butt welding connection and socket welding connection, both of which are coded as “6” in the national standard GB/T308 model compilation.

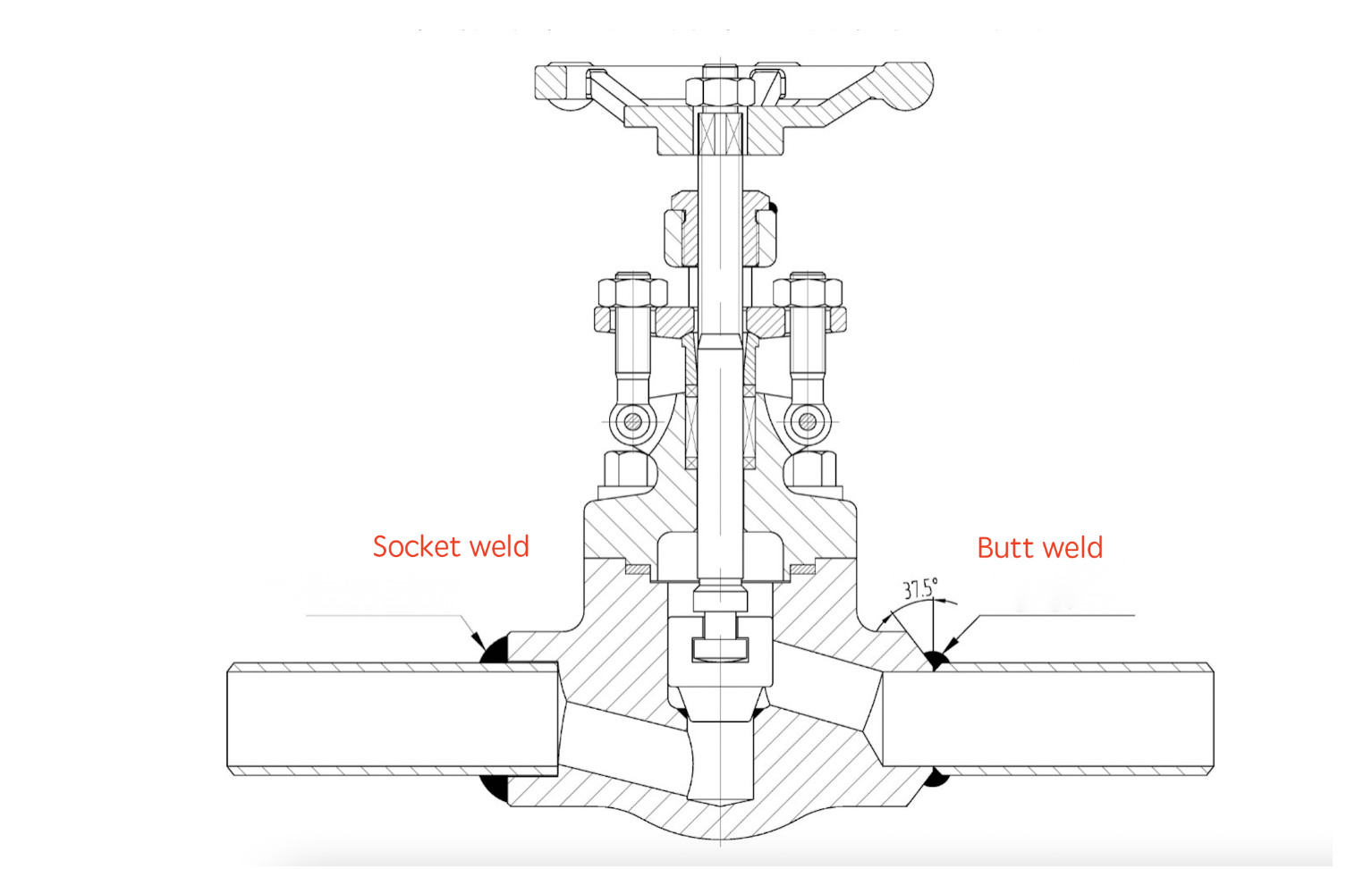

- Butt welding connection: The valve connected by butt welding has a sloping groove, and the groove size is machined according to the outer and inner diameters of the pipeline. The processing method of valve welding grooves is detailed in the national standard GB/T12234. Generally, the groove of valves has three angles according to the standard, but small-diameter valves below 50 sometimes only have one angle. All valves can be connected by butt welding.

- Socket welding connection: Socket welding connection is the process of inserting a pipe into the valve body for welding, which looks like an internal threaded valve but without threads. The inner diameter of the socket is 1-2mm larger than the outer circumference of the pipe. Most of the valves connected by socket welding are Dalian-style forged steel gate valves, globe valves, and check valves with a diameter of 50 or less, with black skin (a surface treatment process of blackening, oxidation, and rust prevention, and now also phosphating treatment, with gray color). The design and manufacturing standards are API602 and JB-T7746 for compact steel valves.

2、 Comparison of butt welding and socket welding connection methods for valves:

- Socket welding cannot undergo radiographic testing, but magnetic particle or penetrant testing can be performed. After welding, there will be gaps in the part of the pipe inserted into the valve body, so socket welding is not suitable for pipeline systems that are sensitive to crevice corrosion and have high cleanliness requirements.

- Butt welding can be subjected to radiographic, magnetic particle, or penetrant testing, and the analysis of post-weld strength, stress conditions, etc. shows that butt welding is superior to socket welding and can undergo strict testing.

So for high-demand working conditions that cannot accept even a slight defect, a butt welding connection is chosen for convenient 360-degree inspection. Socket welding can be used for valves below 2500LB and DN50.

3、Schematic diagram of butt welding connection and socket welding connection:

Please follow and like us: