In fluid control systems, particularly in high-pressure, high-temperature environments, the integrity of connections between pipes and instrumentation is paramount. One of the most reliable solutions for leak-tight connections is the double ferrule fitting. These fittings are widely used across various industries, including oil and gas, chemical processing, and pharmaceuticals, where precision and safety are critical.

In this article, we will dive into the working principle of double ferrule fittings, explaining how their unique design ensures a secure, leak-tight connection, while also being easy to install, maintain, and inspect. We’ll also explore their advantages over other fitting types and the key applications that benefit most from their use.

What is a Double Ferrule Fitting?

Double ferrule fitting, also known as twin ferrule or two-ferrule fitting, is a mechanical compression fitting designed to connect tubes in fluid systems. These fittings consist of several core components:

- Fitting Body: The primary housing where the tube is inserted.

- Front Ferrule: The sealing component that forms a tight bond with the tubing.

- Back Ferrule: Provides additional gripping force to hold the tubing securely.

- Nut: Tightens the ferrules around the tube to complete the seal.

Double ferrule fittings work through the combined action of these components to create both a leak-tight seal and a mechanical grip on the tubing.

The Double Ferrule Design and Its Function

At the heart of the double ferrule fitting’s reliability is its two-ferrule design. Each ferrule plays a specific role in ensuring both sealing and gripping.

- 1. Front Ferrule: The front ferrule is responsible for the primary sealing function. When the nut is tightened, the front ferrule moves forward, wedging itself between the fitting body and the outer diameter of the tubing. This action creates a tight, leak-proof seal on the tube’s surface.

2. Sealing Mechanism: The front ferrule creates a metal-to-metal seal against both the tube and the fitting body, preventing fluid from escaping even under high pressure or temperature variations.

3. Back Ferrule: The back ferrule’s role is to grip the tubing securely. When the nut is tightened, it drives the back ferrule axially forward. As the back ferrule advances, it applies a radial swaging action that bites into the tube, holding it firmly in place without deforming or weakening the tubing.

4. Gripping Mechanism: The back ferrule’s unique geometry helps prevent tube movement caused by vibration or thermal expansion. This feature is particularly important in dynamic systems where tube integrity must be maintained over long periods of time.

Together, the two ferrules function synergistically to ensure both a gas-tight seal and a strong grip on the tubing, providing unparalleled reliability in critical applications.

Advantages of Double Ferrule Fittings

1. Leak-Tight Sealing

Double ferrule fittings excel in providing leak-tight connections, even in extreme conditions. This makes them ideal for high-pressure systems, where leak prevention is critical to maintaining system integrity and safety.

2. Vibration Resistance

In systems that experience significant vibration or mechanical stresses, the back ferrule’s radial grip on the tubing provides robust resistance against loosening or leakage caused by vibrations.

3. Reusability and Ease of Installation

Double ferrule fittings are easy to install and can be disassembled and reassembled multiple times without losing their sealing properties. This makes them highly cost-effective for maintenance, as parts can be reused without compromising safety or performance.

4. No Need for Special Tools

Unlike welded or brazed connections, double ferrule fittings do not require specialized tools or equipment for installation. A simple wrench is enough to achieve a secure connection.

5. Compatibility with Multiple Tube Materials

These fittings are available in a variety of materials, including stainless steel, brass, and other corrosion-resistant alloys, making them suitable for a wide range of applications. They are compatible with different tubing materials, such as stainless steel, copper, and plastic.

Key Applications of Double Ferrule Fittings

1. Oil and Gas Industry

In the oil and gas industry, where systems operate under extreme pressures and temperatures, double ferrule fittings are often used to ensure reliable connections in pipelines, flow meters, and pressure control equipment. Their ability to withstand harsh environments makes them ideal for subsea, offshore, and onshore applications.

2. Chemical Processing

In chemical processing plants, safety is a primary concern due to the hazardous nature of many chemicals. Double ferrule fittings provide leak-tight seals that prevent exposure to toxic or corrosive substances. They are commonly used in instrumentation systems that monitor temperature, pressure, and flow in chemical reactors.

3. Pharmaceuticals

In pharmaceutical manufacturing, where sterility and cleanliness are critical, double ferrule fittings help maintain the integrity of cleanroom environments. Their precision in sealing and easy installation ensures that no contaminants are introduced into the system.

4. Power Generation

Power plants rely on precise fluid control in systems such as steam turbines, boilers, and cooling systems. Double ferrule fittings provide the reliability needed to prevent leaks and ensure continuous operation, making them a trusted choice in both nuclear and conventional power plants.

Installation Process for Double Ferrule Fittings

One of the key benefits of double ferrule fittings is their ease of installation. Below is a step-by-step guide to proper installation:

- 1. Tube Preparation: Ensure that the tubing is clean, smooth, and cut squarely. Deburr the ends to prevent any damage during the tightening process.

- 2. Insert the Tube: Slide the nut and ferrules onto the tube. Ensure that the front ferrule is positioned towards the fitting body, and the back ferrule is behind it.

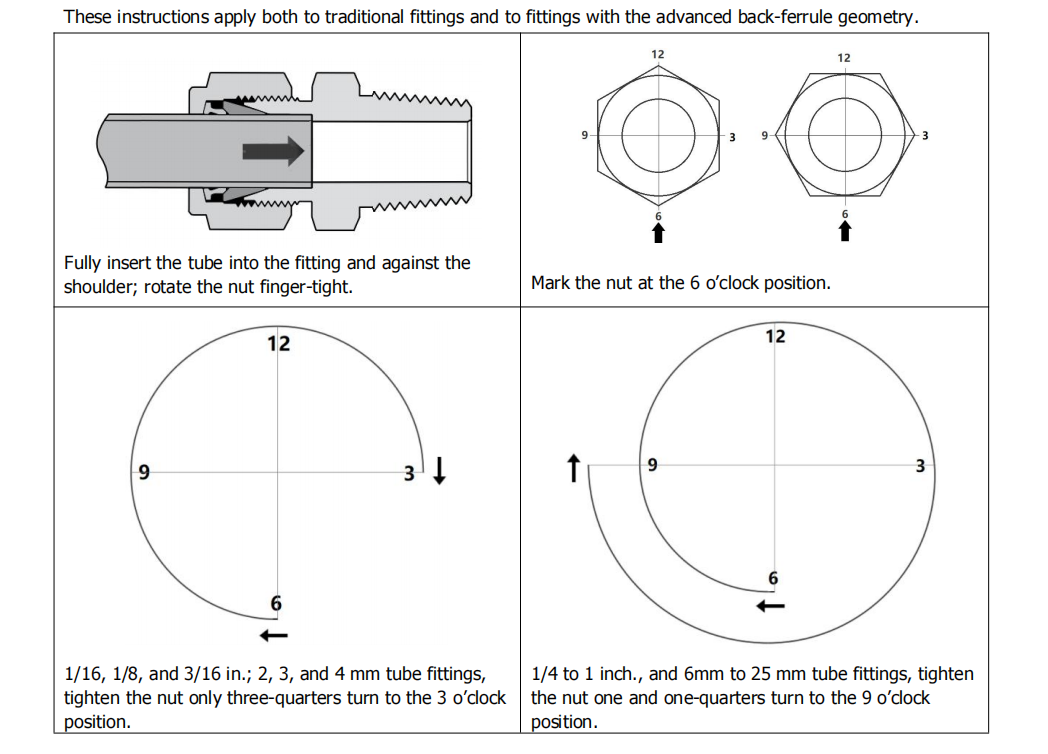

- 3. Hand-Tighten the Nut: Insert the tube into the fitting body until it bottoms out. Hand-tighten the nut to ensure the ferrules are seated properly.

- 4. Final Tightening: Using a wrench, tighten the nut by approximately 1¼ to 1½ turns past hand-tight. This compression action engages the ferrules, securing the tubing and creating a leak-tight seal.

- 5. Inspection: Use a gap inspection gauge to ensure the fitting is correctly tightened according to manufacturer specifications.

Common FAQs about Double Ferrule Fittings

1. How many times can I remake a double ferrule fitting?

Double ferrule fittings can typically be remade multiple times without losing their sealing ability, as long as the ferrules and tubing are not damaged.

2. What materials are double ferrule fittings made from?

These fittings are available in various materials, including stainless steel, brass, carbon steel, and other high-performance alloys